CTD and Rosette Setup¶

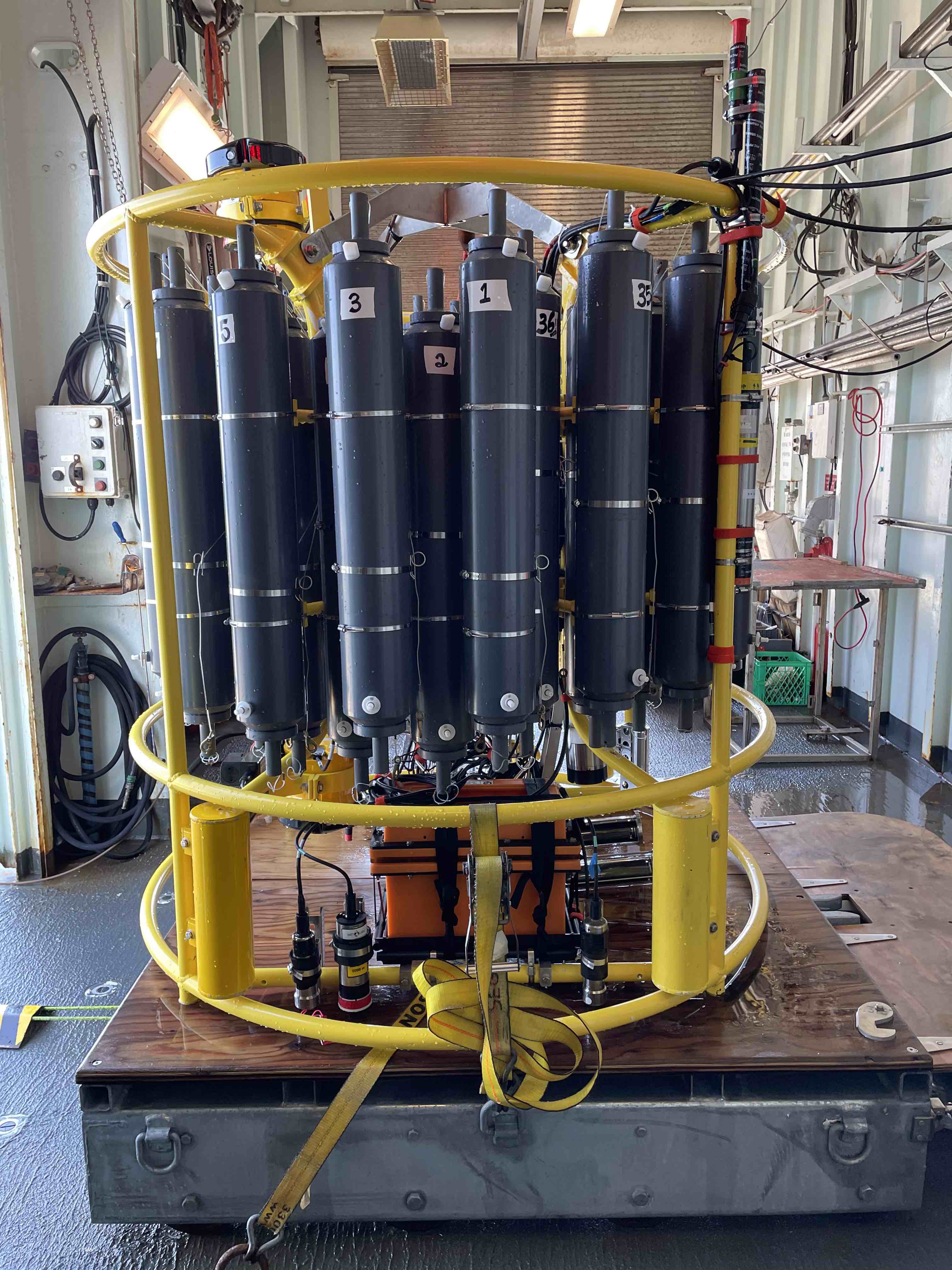

For A22-2021 the new STS 36 place yellow rosette and bottles, built in 2017, were used. The rosette and bottles were built before P06 2017, making this the seventh time this package has been deployed. The bottles were made with new PVC, with new non-baked o-rings and electro-polished steel springs. This represents a change from the past, where on GO-SHIP cruises using ODF equipment before P06 2017 o-rings were baked for 3 days at 100°C at 1-3 Torr in a sweeper gas of hydrogen. Springs used to be painted and Tygon tubing added to the ends to prevent paint wearing away from bottle firing. As on P06 2017 no sample contamination has been noticed by the change in o-rings and springs. The package used on A22-2021 weighs roughly 1500 lbs in air without water, and 2350 lbs in air with water. The package used on A22-2021 weighs roughly 950 lbs in water. In addition to the standard CTDO package on GO-SHIP cruises three chipods, two LADCPs, and one experimental CTD were mounted on the rosette. During the cruise we encountered a handful of problems, most notably noisy altimeter data and bottle firing issues. We describe all of the above in more detail in the sections below.

Underwater Sampling Package¶

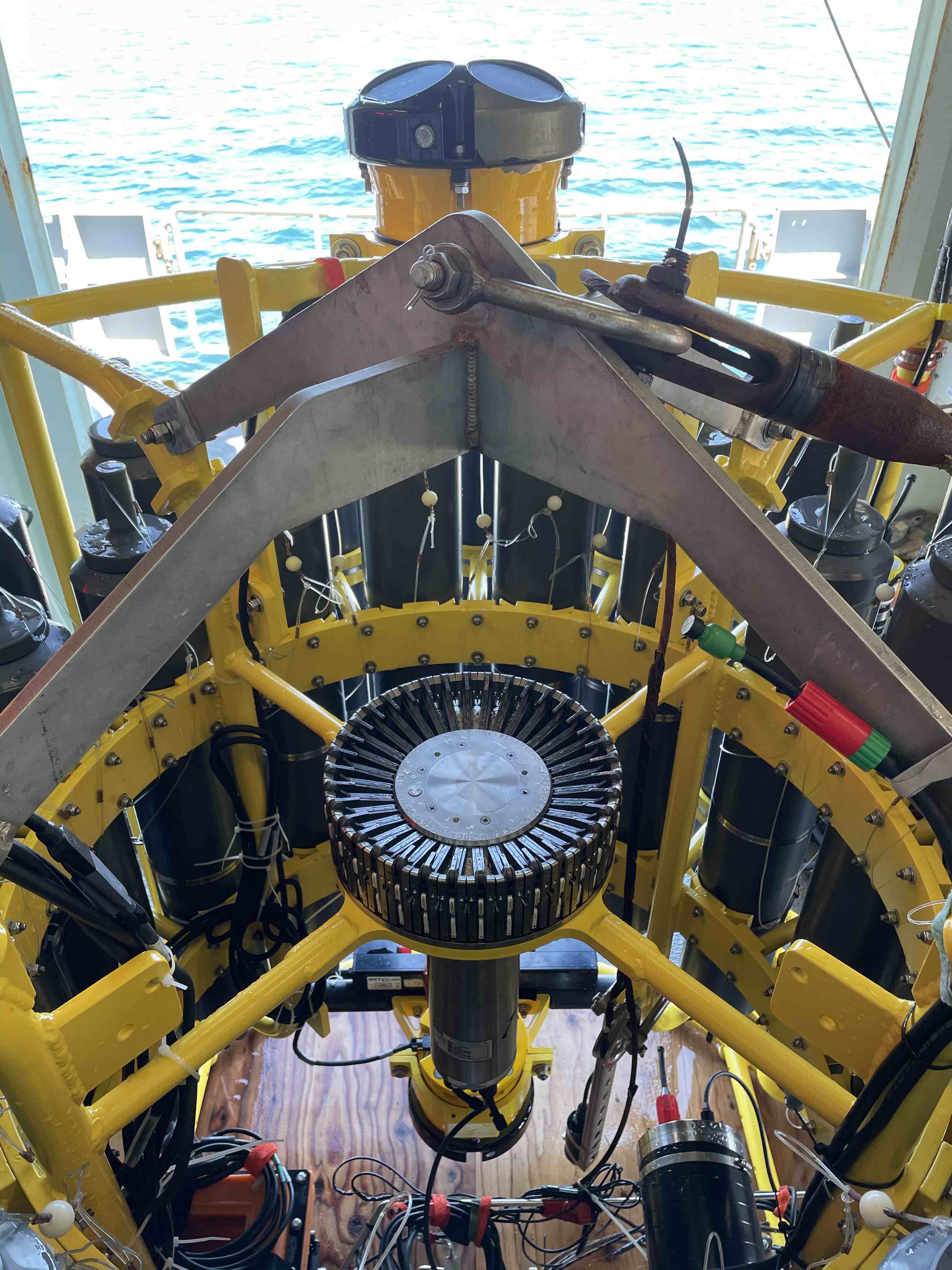

CTDO/rosette/LADCP/UVP/chipod casts were performed with a package consisting of a 36 bottle rosette frame, a 36-place carousel and 36 Bullister style Niskin bottles with an absolute volume of 10.6L. Underwater electronic components primarily consisted of a SeaBird Electronics housing unit with Paroscientific pressure sensor with dual plumbed lines where each line has a pump, temperature sensor, conductivity sensor, and exhaust line. A SeaBird Electronics membrane oxygen sensor was mounted on the “primary” line. A reference thermometer, Rinko oxygen optode, transmissometer, chlorophyll-a fluorometer, and altimeter were also mounted on the rosette. Chipod, LADCP, and UVP instruments were deployed with the CTD/rosette package and their use is outlined in sections of this document specific to their titled analysis.

CTD and cage were horizontally mounted at the bottom of the rosette frame, located below the carousel for all stations. The temperature, conductivity, dissolved oxygen, respective pumps and exhaust tubing was mounted to the CTD and cage housing as recommended by SBE. The reference temperature sensor was mounted between the primary and secondary temperature sensors at the same level as the intake tubes for the exhaust lines. The transmissometer was mounted horizontally on the lower LADCP brace with hose clamps around both of its ends, avoiding shiny metal or black tape inside that would introduce noise in the signal. The oxygen optode, fluorometer, and altimeter were mounted vertically inside the bottom ring of the rosette frames, with nothing obstructing their line of sight. One 300 KHz bi-directional Broadband LADCP (RDI) unit was mounted vertically on the bottom side of the frame. Another 300 KHz bi-directional Broadband LADCP (RDI) unit was mounted vertically on the top side of the frame. The LADCP battery pack was also mounted on the bottom of the frame. The LADCP and LADCP battery pack were mounted next to each other at the beginning of the cruise. If we imagine the LADCP battery being north on the rosette, the LADCP was mounted east, the CTD mounted south, and the UVP mounted west.

Equipment |

Model |

S/N |

Cal Date |

Stations |

Group |

|---|---|---|---|---|---|

Rosette |

36-place |

Yellow |

– |

901-90 |

|

CTD |

SBE9+ |

0914 |

– |

901-90 |

|

Pressure Sensor |

Digiquartz |

110547 |

Feb 5, 2021 |

901-90 |

|

Primary Temperature |

SBE3+ |

32309 |

Feb 2, 2021 |

901-90 |

|

Primary Conductivity |

SBE4C |

43399 |

Nov 25, 2020 |

901-90 |

|

Primary Pump |

SBE5 |

51871 |

– |

901-90 |

|

Secondary Temperature |

SBE3+ |

32380 |

Feb 2, 2021 |

901-90 |

|

Secondary Conductivity |

SBE4C |

41880 |

Dec 4, 2020 |

901-90 |

|

Secondary Pump |

SBE5 |

58690 |

– |

901-90 |

|

Transmissometer |

Cstar |

1803DR |

Aug 9, 2019 |

901-90 |

|

Fluorometer Chlorophyll |

WetLabs ECO-FL-RTD |

1156 |

– |

901-90 |

|

Dissolved Oxygen |

SBE43 |

430255 |

Nov 13, 2020 |

901-90 |

|

Oxygen Optode |

JFE Advantech Rinko-III |

0296 |

Apr 7, 2017 |

901-90 |

|

Reference Temperature |

SBE35 |

0105 |

Feb 9, 2021 |

901-90 |

|

Carousel |

SBE32 |

0187 |

– |

901-43 |

|

Carousel |

SBE32 |

1178 |

– |

44-90 |

|

Altimeter |

Valeport 500 |

53821 |

– |

901-59, 61-90 |

|

Altimeter |

Valeport 500 |

48049 |

– |

60 |

|

DL LADCP |

Teledyne RDI WH300 |

24497 |

– |

901-90 |

|

UL LADCP |

Teledyne RDI WH300 |

12734 |

– |

901-90 |

|

UVP |

– |

207 |

– |

901-90 |

|

D2 CTD |

D2 CTD |

01-1563 |

– |

901-45 |

|

D2 CTD |

D2 CTD |

01-1565 |

– |

46-90 |

|

Chipods |

Chipod |

2008 Ti44-5 |

– |

901-90 |

|

Chipods |

Chipod |

2027 TI44-3 |

– |

901-90 |

|

Chipods |

Chipod |

2030 Ti44-11 |

– |

901-90 |

Package sensor setup from south.¶

Package sensor setup from east.¶

Package sensor setup from north.¶

From left to right: oxygen optode, fluorometer, LADCP battery pack, altimeter.¶

Package setup from southwest, with CTD in foreground and downlooking chipod to the right.¶

Packaget setup from west.¶

Package setup from west, top view.¶

Winch and Deployment¶

The aft DESH-5 winch deployment system was used for all stations. The rosette system was suspended from a UNOLS-standard three-conductor 0.322” electro-mechanical sea cable. The sea cable was already terminated from the previous leg (A20) and no electrical or mechanical issues occurred on A22.

The deck watch prepared the rosette 10-30 minutes prior to each cast. The bottles were cocked and all valves, vents, and lanyards were checked for proper orientation. Any biofouling noted was cleaned off the outside of the rosette before the next cast, and the inside of the bottles were checked for biofouling and sprayed down. LADCP technician would check for LADCP battery charge, prepare instrument for data acquisition, and disconnect cables. Once stopped on station, the Marine Technician would check the sea state prior to cast and decide if conditions were acceptable for deployment. The rosette was moved from the sampling bay out to the deck using the Thompson’s new winch-driven cart. Once on deck, the ratchet straps connecting the rosette to the cart were removed and sea cable slack was pulled up by the winch operator. CTD watch standers would then turn on the deckbox and begin data acquistion, and the cast would begin. Recovering the package at the end of the deployment was the reverse of launching. Once rolled back into the sampling bay, the ship crew secured the cart to the deck using additional ratchet straps. The carousel was rinsed and sensors were cleaned (as described below) after every cast, and then samplers were allowed to begin collecting water.

Maintenance and Calibrations¶

During A22-2021 routine maintenance was done to the rosette to ensure quality of the science done. Actions taken included rinsing all electrical instruments on the rosette down with fresh water after each cast and adjusting hose clamps and guide rings as needed such that lanyards had appropriate tension. Care was taken not to rinse the spigots and other parts of the bottle that might be touched by samplers in order to not contaminate the samples. After each cast, syringes of fresh water were connected to the plumbed lines to rinse the sensors and allow them to soak between casts. While in freezing conditions, water was drained after rinse to avoid freezing in the plumbing. Overhead heaters recently installed on the Thompson were run while in freezing or near-freezing conditions. The rosette was routinely examined for valve and o-ring leaks, which were maintained as needed. SBE35RT temperature data was routinely downloaded each day.

Every 20 stations, the transmissometer windows were cleaned and on deck blocked and un-blocked voltage readings were recorded prior to the cast. The transmissometer was also calibrated before the start and after the end of science operations.

Logs¶

In port: Preparation of the CTD and rosette was minimal as it had nearly the same setup as A20 2021, which had just been completed. UVP arrived in St. Thomas and was mounted opposite the ADCP. Downlooking chipod mounting pole was swapped out to allow the sensor to be closer to the leading edge of the rosette. Additional integrity checks on the rosette, such as checking lanyard angles, o-ring and lanyard replacement, and spigot movement waited until being underway to be checked as lower priority tasks. We are using a new mounting system for the downward looking LADCP which has the LADCP clamped facing inward instead of outward, which will cause problems if we need to change that LADCP in rough weather.

April 21, 2021

90001 – First test cast aborted around 350 m. Tube connecting the primary and secondary pumps (attached in port to prevent fouling of the plumbing lines) was not removed prior to start of cast, identified initially in data by large differences in primary/secondary T/C lines.

90002 – Test cast to 4500 m. UVP did not turn on during ascent from initial 20 m soak. Tried soaking again (at 20 m), still did not activate. Upon recovery, data from cast 90001 was present but nothing was recoreded from 90002. The assumption is that the rosette was not on deck long enough to fully power cycle the UVP.

April 22, 2021

00101 – UVP turned on as expected; no issues noted. Adjusted guide ring on bottle 30.

00201 – Bottles 4, 5, 6, and 9 were leaking, 11 and 12 had loose vents.

00301 – Fired surface bottle (#23) on the fly due to large swell. Rosette sat at 35 m for longer than standard while deck crew prepared for recovery.

00401 – Adjusted guide ring on bottles 29, 30, 32 before cast.

00501 – No issues noted.

00601 – No issues noted.

April 23, 2021

00701 – Bottle 25 did not close, top cap was stuck against rosette frame crossbar. Entire bottle was moved downward to prevent that from happening again.

00801 – No issues noted.

00901 – No issues noted.

01001 – ADCP data reported in multiple files, suspected power issues. Swapped out cable and battery.

April 24, 2021

01101 – No issues noted.

01201 – Bottle 3 did not fire.

01301 – No issues noted.

01401 – Surface bottle (#36) was too cold, closer to temperature of 400-500 m bottles. Inspecting after cast, the bottom end cap was loose enough to close itself, likely early closure. Adjusted guide ring to prevent early closures.

April 25, 2021

01501 – No issues noted.

01601 – Adjusted guide ring for bottle 32 before cast. Miscommunication with winch during bottom approach: stopped early (~20 m from bottom), fired bottle as normal, after which winch continued downward briefly. On way up, bottle 2 was misfired shortly after leaving the bottom.

01701 – No issues noted.

01801 – No issues noted.

April 26, 2021

No issues noted for stations 01901-02101.

April 27, 2021

02201 – No issues noted.

02301 – No issues noted.

02401 – ~160 m salnity spike (just primary line?)

02501 – No issues noted.

02601 – No issues noted.

02701 – Taking less than half a rosette worth of bottles, fired odd bottles to make recovery easier (uniformly distributed weight instead of all to one side). Was confusing for analysts in other groups, will not do again.

02801 – 115 m depth bottle mistakenly skipped, shifted remaining bottles appropriately.

April 28, 2021

02901 – No issues noted.

03001 – Adjusted guide rings on 2, 10, 12, 14, 19, 32-36 before cast.

03201 – Raised bottle 26 up before cast, may have been firing late because of poor placement.

03301 – Bottle 3 did not close.

April 29, 2021

03401 – Bottle 22 did not close. Adjusted bottle 23 height since it was getting stuck on crossbar.

03501 – Bottle 3 did not close. Replaced carouse latch for bottle 33 and raised bottle 22 to improve lanyard angle.

03601 – Adjusted guide ring son bottle 2, 8, 9, 17, 19, 21, 24.

03701 – Air vent on bottle 35 was not fully shut.

April 30, 2021

03801 – Salinity signal was a little spiky during soak but quickly remedied itself (may just be bottom of mixed layer or something pulled through lines?).

03901 – Bottle 26 guide ring adjusted upward.

04001 – No issues noted.

May 1, 2021

04101 – Bottle 3 did not fire, bottle 16 was leaking due to loose air vent. Bottle 26 accidentally misfired on fly.

04201 – Bottle 3 did not fire.

04301 – Adjusted guide rings on bottles 17-21, 23, 32. Skipped firing bottle 3, will repair “spare” (i.e. primary) carousel during cast and replcae during transit to next.

May 2, 2021

04401 – Adjusted guide ring on bottle 15. Replaced carousel with primary, after swapping solenoid #12.

04501 – No issues noted.

04601 – D2 1563 replaced with 1565 at PI’s request. Adjusted guide rings on bottles 11, 15, 19, 21, 23, 29, 30, 33, and 35. UVP did not show much change in surface during soak but was fine during cast; suspected the upper water column did not have much to photograph.

04701 – Downlooking chipod was remounted with thicker rubber between unistruct and frame, hoping to stop the shifting which is occurring during deployment, cast, or recovery.

May 3, 2021

04801 – Spigot on bottle 35 was not fully closed.

04901 – Altimeter spiking during bottom approach.

05001 – Replaced spigot o-rings for bottle 16 before cast, was sticky and hard to fully close. Altimeter continuing to be spiky during bottom approach.

May 4, 2021

05101 – Bottle 35 was leaking, broken air vent o-ring – replaced before next cast. Also replaced for bottles 5, 7, and 9.

05201 – Altimeter continuing to be spiky during bottom approach.

05301 – Adjusted guide rings on 18, 29-34 before cast. Altimeter did not kick in until ~50 m from bottom, then was noisy during the entire bottom approach; stopped ~20 m from bottom to be conservative. Bucket testing afterward did not reveal any obvious problems and comparison with a new (presumably function) altimeter had the same results.

05401 – Adjusted guide rings on 8, 10, 36. Same altimeter behavior.

May 5, 2021

05501 – Same altimeter behavior. Will leave as is since the behavior is now predictable, rather than introduce new unknowns. Bottle 25 fired quickly after stop, rather than waiting 30 seconds. Spigot pull tab on bottle 6 broken on recovery.

05601 – Same altimeter behavior.

05701 – Replaced o-rings and broken pull tab on bottle 6 before cast.

May 6, 2021

05801 – Spiky transmissometer data, tape on hose clamp came loose. After cast, wrapped electrical tape in a spiral around hose clamp to prevent it from peeling up.

05901 – Altimeter seems to be getting worse, swapping in TGT’s 48049 before cast 60.

06001 – Adjusted guide rings on 10, 18, 20, 24, 29-33, 35, 36. Altimeter not much different. Swapping back to original (S/N 53821) and also swapping to TGT’s cable to see if that is the issue.

06101 – Altimeter behavior largely the same. Ultimately decided noise is due to rosette angle and bathymetry scattering the pings, the effect of which is reduced closer to the bottom.

May 7, 2021

06201 – Transmissometer spike ~1130 m.

06301 – Adjusted guide rings on the usual bottles. After cinching down with drill, tightened every hose clamp further with a screwdriver. Was able to get at least 1/4 turn out of each, drill not as powerful as it used to be?

06401 – No issues noted.

May 8, 2021

06501 – Raining heavily during deployment.

06601 – No issues noted.

06701 – No issues noted.

May 9, 2021

06801 – No issues noted.

06901 – Rubber between top bottle standoff sliding out, removed after cast. Hose clamp was not tightened down so bottle was a little loose.

07001 – At 5 m bottle stop, there was a miscommuncation and the ship rotated to face into the swell. Rotated before bottle fired so sample is highly contaminated.

07101 – Tighted all guide ring hose clamps with screwdriver once again.

May 10, 2021

07201 – No issues noted.

Weather delay for the rest of the day.

May 11, 2021

07301 – Changed top end cap, lanyards contected to it, and o-ring. Miscommunication between shifts led to the interior lanyard (cap to spring) to be changed again.

07401 – No issues noted.

07501 - Bottle 29 vent was not fully closed.

May 12, 2021

07601 – Bottle 2 did not seal all the way, o-ring not well seated – o-ring replaced by night shift (miscommuncation again, o-ring was just recently changed). Inter-lanyards (cap to cap) replaced on bottles 28 and 29.

07701 – Bottle 2 o-ring not well seated again, may have questionable data. Tried to remove any twist in o-ring and re-seat. Gulf Stream currents very strong, large wire angle.

07801 – Inter-lanyard (cap to cap) for bottle 29 was very tight upon recovery, removed shortly after getting on deck. Old one was ~1.5” too short – replaced with a new one of appropriate length before cast 79. Bottle 2 o-ring unseated again, replaced end cap with original one that was working properly.

May 13, 2021

07901 – ADCP having trouble turning on, cast slightly delayed. Rosette drifted upward during bottom bottle stop.

08001 – No issues noted.

08101 – Adjusted guide ring 23, tightened all others with screwdriver. Spigot on bottle #16 is very sticky, replaced before cast 82.

08201 – No issues noted.

May 14, 2021

08301 – No issues noted.

08401 – No issues noted.

08501 – Mixed layer shallow, no good spot to switch to auto-cast.

08601 – Trying bottle stop experiment, fired triplicates at 30, 60, and 90 seconds after stop, at two depths.

08701 – No issues noted. Trying bottle stop experiment, fired triplicates at 30, 60, and 90 seconds after stop, at two depths.

May 15, 2021

08801 – Trying bottle stop experiment, fired triplicates at 30, 60, and 90 seconds after stop, at two depths.

08901 – No issues noted.

09001 – No issues noted.

Sensor Problems¶

SBE 32 Carousel: Another solenoid failure, this time in secondary carousel. Primary was fixed and swapped in on before cast 44. Pictures of swollen solenoid shown below.

Bad solenoid (center), cloudy and raised edge from corrosion.¶

Bad solenoid (left), cloudy and raised edge from corrosion.¶

Altimeter spiking: Ended up just being bathymetry/bad returns. Swapping altimeter and cables made no difference.

Bottle guide rings: Guide rings continually slipped during the whole cruise. In the end, the issue was they were not being sufficiently tightened by the normal drill we used – fixed by hand tightening further with screwdriver.